Audi Production Plant in Mexico. Click image to enlarge |

Article and photos by Lesley Wimbush, renderings courtesy Audi

SAN JOSÉ CHIAPA, Mexico – Goats nibble the sparse grasses along the roadway as we make our way into this dusty village about 184 km south east of Mexico City.

The peaks of the Sierra Madre Oriental and Trans-Mexican Volcanic Mountain belt loom overhead, and while some are still actively volcanic, our driver assures us that their emissions consist mainly of steam.

It’s a tranquil scene, in direct contrast to the chaotic poverty we’d seen en route while travelling through Mexico City – a tragic glimpse into the reality behind the brightly coloured travel brochures. Much of the outskirts of the city consist of squatter’s huts, a jumble of grey masonry surrounded by rusted-out cars, dog carcasses and mounds of garbage. Every toll booth was guarded by unsmiling federates armed with automatic weapons.

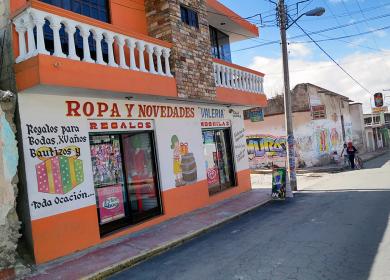

Only 4,500 people live in San José Chiapa, several of whom are out working the fields behind horse-drawn ploughs. Others stand guard over small flocks of sheep, or hawk delicious-smelling chalupas and tortas from tiny, jumbled shops in brightly painted buildings.

Unlikely as it seems, this remote spot will be soon producing some of the world’s finest luxury cars. Only a year ago, Audi broke ground on an 800,000 hectare site that will eventually build the Q5 crossover.

Convoys of dump trucks rumble across the baked red earth, moving past gigantic steel skeletons of what will soon be ultramodern production facilities.

Today we’re attending the groundbreaking ceremony for a “supplier’s park” that will produce many of the car’s components on site.

The 1.3 billion US dollar plant is currently Audi’s biggest single project.

But it was a little more complicated than simply throwing up a manufacturing facility and immediately churning out cars. The site’s remoteness posed more than a few challenges, mainly in establishing an infrastructure to support a manufacturing base.

As of 2014, Audi built more cars outside Germany than they did in – and have adhered to the strict standard of quality that has established them as one of the world’s premier luxury car manufacturers.

So why would a premium car company choose such an unlikely location for a state-of-the-art manufacturing facility?

It isn’t just due to an abundance of cheap labour. Although most of the plant’s employees will be unionized and thus protected from exploitation – Mexican labour is still significantly lower on average than other North American markets (80 percent lower according to the Center for Automotive Research). According to Audi AG Board Member Dr. Bernd Martens, the crucial factor in choosing Mexico for the new plant lies in ease of exportation. Mexico is a member of NAFTA (North American Free Trade Agreement), and can freely trade with the rest of North America. However, less than a third of the 150,000 Q5s rolling off the production line that first year are destined for U.S. and Canada. The remainder are intended for fast-growing global markets, and since Mexico has trade agreements with some 40 other countries worldwide, Audi can freely export without incurring high tariffs. The new plant is located only 250 km from the shipping port of Veracruz, and there’s already an existing railway line.

San José Chiapa. Click image to enlarge |

While the initial production run will contain 65 percent NAFTA parts, eventually all Q5s produced at the plant will contain 90 percent North American parts and components.

One year after beginning the plant’s construction, Audi celebrated the groundbreaking of their “Supplier’s Park”, where some of the 200 companies vying for tenders will produce components. Most of these had been invited to a workshop last year to begin working towards Audi’s APS (Audi Production System) standards and seven companies present at today’s ceremony will be moving in once the park is finished. An on-site training centre will soon begin operation, to ensure that Audis produced here will have exactly the same level of quality as those built in Germany.

The plant will follow Audi’s “Just In Sequence” (JIS) format, and all companies in the supplier’s park will be trained to those specifications. Many of those suppliers will send skilled employees to Ingolstadt, where they will learn on the Audi assembly lines.